8 Ways Sanitising Tunnels Protect Ireland’s Meat Industry

8th October 2025

Why Hygiene Is Ireland’s Competitive Edge

Ireland’s meat industry is globally respected for its quality, traceability, and sustainability. But behind every premium cut is a rigorous hygiene protocol that starts long before the meat hits the shelf. Sanitising tunnels are now central to this process—automated systems that disinfect personnel, tools, and even packaging as they move through production zones.

Whether you’re a local butcher searching for a “hygiene tunnel near me” or a large processor exporting to Asia, these systems are becoming indispensable. They don’t just meet regulatory standards—they exceed them, offering peace of mind in an industry where one slip can mean a costly recall.

Automated Hygiene for Meat Plant Workers

Human error is the Achilles’ heel of hygiene compliance. Sanitising tunnels eliminate this risk by automating the disinfection process for every person entering the facility.

These tunnels typically include:

- Boot washers that scrub and disinfect footwear

- Hand sanitising stations with timed dosing

- Full-body misting systems using food-safe disinfectants

This ensures uniform hygiene across shifts, reducing the risk of pathogens entering production zones. In Ireland, where meat plant hygiene is tightly regulated, these systems help facilities stay audit-ready year-round.

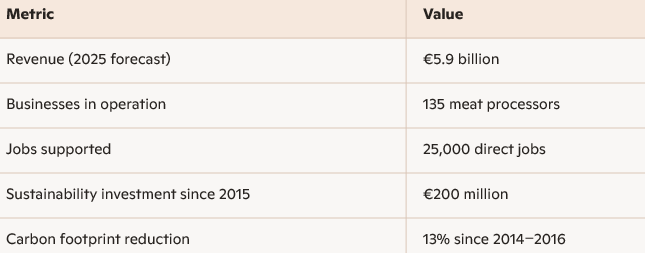

Industry Snapshot: Irish Meat Processing by the Numbers

Here’s a quick look at the current state of the industry:

Cold Room Disinfection Made Easy

Cold rooms are essential for preserving meat, but they’re also prone to microbial growth due to moisture and low airflow. Sanitising tunnels simplify cold room disinfection in Ireland by:

- Using UV-C light to kill bacteria and viruses on surfaces

- Deploying misting systems that reach corners and crevices

- Automating scheduled disinfection cycles to reduce manual labour

This protects meat from spoilage and extends shelf life—especially important for export markets where delays can be costly. Cold room hygiene is no longer a backroom chore; it’s a frontline defence.

Tool Sterilisation for Safer Cuts

Every tool in a meat plant—from hand-sawed blades to knife-sharpening tools—can be a vector for contamination. Sanitising tunnels ensure these tools are disinfected before entering clean zones.

Commonly disinfected tools include:

- Hand saws used for primal cuts

- Knife sharpening tools for precision trimming

- Meat hooks for hanging and transport

By integrating tool racks into the tunnel system, facilities can sterilise entire batches of equipment in minutes. This supports HACCP protocols and reduces the risk of cross-contamination between carcasses.

Boosting Butchery Hygiene Standards

Sanitising systems for butcheries are now available in compact formats, making them accessible to small and medium-sized businesses. These systems help local shops:

- Meet national hygiene standards

- Reduce reliance on manual cleaning

- Improve customer trust through visible safety measures

For butcheries competing with supermarkets, hygiene is a key differentiator. A sanitising tunnel at the entrance sends a clear message: “We take your health seriously.”

Reducing Pathogen Risk with UV-C Technology

UV-C light is a powerful tool in the fight against pathogens. Sanitising tunnels equipped with UV-C systems offer:

- Chemical-free disinfection that’s safe for food contact

- Rapid kill rates for bacteria, viruses, and mould spores

- Low maintenance compared to chemical systems

This technology is especially useful in areas where water-based disinfection isn’t feasible. It’s also ideal for packaging zones, where residue-free sanitation is critical.

Enhancing Export Readiness

Ireland’s meat exports are booming, but international markets demand rigorous hygiene standards. Sanitising tunnels help processors meet:

- EU Hygiene Package requirements

- Chinese import protocols

- Retailer-specific audits (e.g., Tesco, Lidl, Carrefour)

By automating hygiene, facilities can pass inspections with confidence and avoid costly delays. It’s not just about meeting standards—it’s about exceeding them to stay competitive.

Improving Workflow Efficiency

Sanitising tunnels aren’t just about hygiene—they’re about speed. By integrating into production lines, they:

- Reduce bottlenecks at entry points

- Minimise downtime between shifts

- Lower labour costs by automating cleaning

This is especially valuable in high-volume facilities where every minute counts. Hygiene becomes part of the workflow, not a disruption.

Reinforcing Brand Trust

In today’s market, transparency is everything. Sanitising tunnels are a visible, tangible commitment to safety.

They reassure:

- Inspectors during audits

- Retail buyers evaluating suppliers

- Consumers who value traceability

Whether you’re showcasing your facility on social media or hosting a buyer tour, these systems make a strong impression. They’re not just functional—they’re symbolic.

Hygiene Innovation Is Reshaping Ireland’s Meat Industry

Sanitising tunnels are no longer just a hygiene accessory—they’re a cornerstone of operational excellence in Ireland’s meat sector. As consumer expectations rise and export markets tighten their safety protocols, the industry must evolve beyond manual cleaning and reactive compliance.

These systems offer a proactive, scalable solution that touches every aspect of production—from the boots on the floor to the blades in the cold room.

What makes sanitising tunnels so transformative is their ability to unify hygiene, efficiency, and trust. They don’t just clean—they standardise.

They don’t just protect—they prove your commitment to safety. And they don’t just serve the present—they future-proof your facility against the next wave of regulatory and consumer demands.

Whether you’re a local butcher seeking a hygiene tunnel near me or a multinational processor preparing for international audits, the message is clear:

Hygiene is no longer a checkbox—it’s a competitive advantage.

Key Takeaways:

- Sanitising systems for butcheries help small shops meet big standards

- Cold room disinfection in Ireland is streamlined and automated

- Boot washers, meat hooks, hand saws, and knife sharpening tools are protected from cross-contamination

- UV-C and misting tunnels offer chemical-free, high-impact sanitation

- Workflow efficiency and brand reputation both benefit from visible hygiene protocols

In an industry built on trust, transparency, and taste, sanitising tunnels are the silent guardians of quality. They’re not just cleaning your facility—they’re elevating your brand.